Why We Only Make Epoxy Surfboards

Why We Only Make Epoxy Surfboards

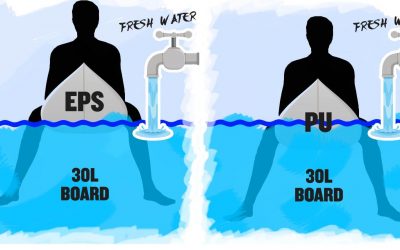

At SBSboards we ensure that every Surfboard is designed and manufactured to the highest possible standards using only the best materials available. We continually strive to better ourselves with every board we make, repeatedly improving board design, tuning performance and construction materials, all in our endeavour to create great performance surfboards that are light, strong and durable for any wave rider.

From our very inception SBS boards have favoured the higher performance materials such as epoxy and now use exclusively only Epoxy resin on all our shaping and manufacturing of our surfboards and SUP ranges. We have the belief and mission statement to make the best surfboards we can with the highest performance possible, which is why we chose Epoxy. Over the years the feedback from customers and Team riders on the performance advantages and construction benefits have always been positive. We have found that epoxy is the superior resin and is our number one choice.

Why is Epoxy better than traditional methods

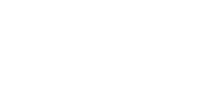

Epoxy surfboards are stronger, lighter & tougher than traditional construction techniques compared to the cheaper materials like (PU) polyester/polyurethane fibreglass boards. It’s widely known that epoxy surfboards are around 30% lighter and 20% Stronger than traditional polyester/polyurethane fibreglass boards and it’s for this reason we use Epoxy “ As who doesn’t want a lighter, stronger surfboard”

Stronger

We are so confident in our construction techniques at SBS Boards that we regularly demonstrate its strength and toughness compared to other poly/pu. This high strength and durability gives us the confidence that if you drop or knock an SBS board it is less likely to break or dying compared to a standard poly/pu board, therefore helping your SBS Board to stay stronger for longer giving you great value for money as you won’t have to replace your board as often.

Whiter

The epoxy resin can be much brighter and whiter which is why our boards are some of the brightest and whitest in the UK. Not only this it helps maintain the rigidity of the construction longer keeping that fresh board look and feel for longer

Lighter

Epoxy Resin is well-known for laminating a lot lighter than polyester on surfboards This allows for a stronger strength to weight ratio helping to keep the board lighter and the glass fibre to flex more efficiently. If you have ever picked up an epoxy EPS and then a standard PU polyester board you will notice the massive difference in weight. This weight difference can lead to huge differences in your surf performance as it can give the board incredible flex speed and response making your board feel super sensitive and responsive and also helping to lower your swing weight in turns

Better Flex

Epoxy is more flexible than polyester (PU) and maintains the lively flex pattern over time that is typically associated with a new board. Throughout our range, we use Epoxy and EPS construction. which allows us to make lighter, stronger, faster, stiffer, more buoyant and more responsive surfboards than a standard PU construction. Our boards will also keep that lively flex and “pop” over time whereas a more traditional poly-board might become less responsive and flexible with use. The quicker and more responsive flex from Epoxy surfboards especially in our new rapid flex surfboards giving your faster acceleration in the turns and more speed over flatter sections.

Our Construction Our superfused, closed cell EPS foam core is stronger than standard Eps foam plus its more water resistant not allowing any water to pass through and keeping your boards free of water should you get a ding. Our superfused high-density EPS foam core is much lighter than a polyurethane core found in a traditional POLY/PU board. This makes for a less toxic and more environmentally friendly board, that is stronger and lighter than a typically POLY/PU Board. The foam used in the construction of the cores in the majority of SBS Boards is a superfused expanded polystyrene (EPS) comprised of tiny beads fused and almost welded together to form a strong lightweight core, with a lower impact on the environment and less hazardous to Human health.

If you compare an SBS Surfboard to a typical standard polyurethane surfboard you will immediately feel the difference in weight instantly. POLY/PU construction typically uses a three-pound foam (1.3kg) which means if you had a one-foot cube of foam it would weigh three pounds, expanded polystyrene (EPS), is typically a one-pound foam (453g). Therefore on average, you can lose a third of the weight just from the foam making a huge difference between the 2 types of construction. Using EPS and epoxy allows us to make stronger lighter more buoyant boards, in turn improving paddling speed, planning speed as well as reaction time on the board by decreasing swing weight and making the board feel very responsive with a very reactive flex.

Throughout our range, we use Epoxy, EPS as this construction technique allows us to make lighter, faster, stiffer, more responsive, and stronger surfboards. Our boards will also keep their pop over time whereas a more traditional poly-board might become more flexible with use. We are so confident in our construction techniques at SBS Boards that we regularly demonstrate its strength and toughness compared to other poly/pu. This high strength and durability gives us the confidence that if you drop or knock an SBS board it is less likely to break or ding compared to a standard poly/PU board, therefore helping your SBS Board to stay stronger for longer giving you great value for money as you won’t have to replace your board as often.

There has been increasing movement over the last decade towards alternative sustainable materials such as ECO foams, carbon fiber or a natural combination of epoxy resins, something as a surfboard manufacturer we are continually exploring and developing to try and use sustainable new age materials that are less harmful to the environment and human health whilst being stronger and lighter than the older styles of surfboard construction.

This is the main reason why you might see some of the best surfers in the world competing on the world tour using epoxy boards, 11 times world champion Kelly Slater seems to ride them pretty regularly pushing and developing boards that have a lower carbon footprint and last longer and still perform, this can only be great for the sport of surfing.

Higher Performance

Epoxy surfboards maintain their lively flex longer than PU boards, that flex is generally quicker and more responsive giving your faster acceleration in the turns and more speed over flatter sections. Epoxy Resins have some incredible performance advantages over polyester Just to leis a few… Epoxy Resin has much Better adhesive qualities as well as superior strength and flex properties. Structurally epoxy surfboards exhibit greater tensile strength meaning more durable in the surf and to dings. Epoxy strength and modulus are close to double that of polyester, thus its Improved resistance to fatigue and microcracking. This helps to keep that original flex for years were as the flex responsiveness can be lost over time on a PU board. This also helps reduced degradation from water ingress giving the epoxy a much higher resistance to osmosis.

Better for the environment

We use epoxy resin because it’s much stronger and less toxic than polyester resin. Polyesters resins contain styrene which is subject to increasingly stringent controls on emissions. Epoxies do not generally cause any problems with atmospheric pollution and epoxy resin has 75% fewer VOCs (Volatile Organic compounds) contained in the resin itself and two-thirds fewer VOCs are released into the atmosphere than from polyester resin (VOCs are a source of air pollution and can be a significant health hazard).

In our view epoxy is the resins of the future with numerous of different concoctions and applications,Research into renewable, bio-based, epoxy resins such as “super sap” is producing some incredible results, especially when compared to polyester which is less tunable, cheaper more toxic and more, brittle.

Related Posts

The Wave Garden Bristol “First Look”

The Wave Garden Bristol “First Look”The Wave Bristol Has released its first short video of the waves produced by wave garden specifically wave garden cove technology and we got say its looks incredible. ever since the first idea of the wave bristol came about we have...

SUP Clinic Chichester By SBS boards & TJ Boards

We hosted our very first SUP clinic with Partners, TJ boards who are local experts of the Chichester canal. We were lucky enough to have our SUP team rider Narcy who lives in Fuerteventura in the canary island who lives and breast anything water sports. who is...

How To Paddle Faster!

Improving your paddle stroke means catching more waves longer sessions and more fun For anyone starting surfing or even an experienced Surfer will know the feeling of missing a wave by one or two strokes, not quite being in front of the wave as it peels or freaking...

13 Things All Beginner Surfers Need To Know

If you are new to surfing or if something you want to try there are some precautions you should definitely take before jumping in at the deep end Here are our top 13 tips for beginners all the things you will need to know to get you started in your surfing fun and...

Epoxy Surfboards are Better For wave Pools?

Whats Better For Wave Pools (EPS Or PU) If you haven’t been hiding under a rock for the last 2 years then you have probably seen the explosion of wave pool video hit the internet from Kelly's Surf Ranch with endless peeling perfection to BSR Park, N Land in Austin or...

INFLATABLE SUP VS HARD SUP WHAT’S RIGHT FOR ME

As technology and development in inflatable and hard boards change this is something to review every few years as it used to be very clear that hard boards rule the waterways and inflatables had no place and no rivalry to the hardboard but today things are very...